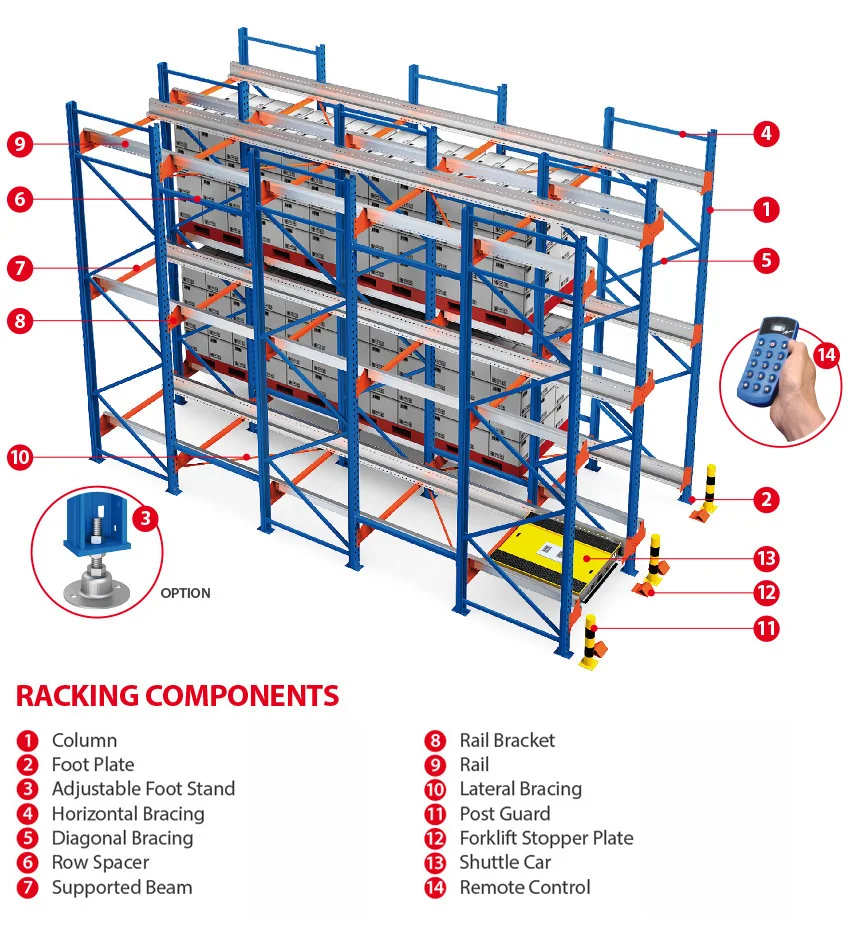

Radio Shuttle System

Radio Shuttle System is a new innovation of Semi-Auto Warehouse Management that can store up to 90% of the total area. With the usage of Shuttle Car that can be controlled by the remote unit. This process of taking cargoes in and out from the rack can be speedy and accurately with the position control system.

Radio shuttle system is nothing short of a magical device when it comes to high intensity palletized storage. It is a highly compact and semi-automated storage solution for palletized goods and does not require loading and unloading using forklifts. There is no extra space between racks for forklift manoeuvring, hence the lanes of the racks are known as channels. One radio shuttle can be used for multiple channels. One channel should contain only one SKU. If one pallet is stored in one channel and the next pallet has to be stored in another channel, then the radio shuttle is unloaded by using a forklift and moved to the other channel. Then, the next pallet is placed. The forklifts place the pallets at the mouth of each rack's channel and the shuttle carries the pallets to the first empty placement and then comes back to the front of the channel. The same process is applied in reverse for the unloading of pallets.

The shuttles are specially designed to bear loads up to 1500 kgs with swift yet controlled motion and they make sure that the least amount of space is left between pallets. This is what makes this system the most compact and space effective system among others. Multiple shuttles can be controlled via a single remote and can fill up or empty a whole channel on receiving a single command. The remote (a tablet operating on network) needs the authentication of an authorized person which reduces the risk of unauthorized access of pallets. The shuttles also come with appropriate safety measures like safety stops, rail end stops, pallet centring etc.

While no aisles lead to maximum space consumption, no forklifts lead to no damage of equipment and racks. The automatic to and fro movement of the pallets without using forklifts results in lower operation costs, more productivity, faster loading/unloading and worriless storage cycles. The radio shuttle (also known as pallet shuttle) system is based on both FIFO and LIFO inventory management principles. If the racks are open on one end, the storing and picking of the pallets is done from the same end which means that the first pallet to go in will be the last one to come out (LIFO). If the racks are open from opposite ends, then the storing and picking will be done on opposite ends without any interference. This means that the first pallet to go in will be the first one to come out (FIFO).

Advantages:

1.) Efficient system of compact storage for warehouse with low levels of sku.

2.) Optimization of storage, loading and unloading stages.

3.) Low level of risks to the warehouse operating staff.

4.) Low level of risks or damage to the equipment-loading machinery & racks.

5.) Removes the need for special fork-lifts.

6.) Very High throughput.

7.) Careful load handling.

8.) Less chances of damage to the racking, due to the fact the forklift does not enters the loading bay.

Hot Tags: Radio Shuttle System, China, suppliers, manufacturers, factory, customized