1. WHAT IS DRIVE IN RACKING?

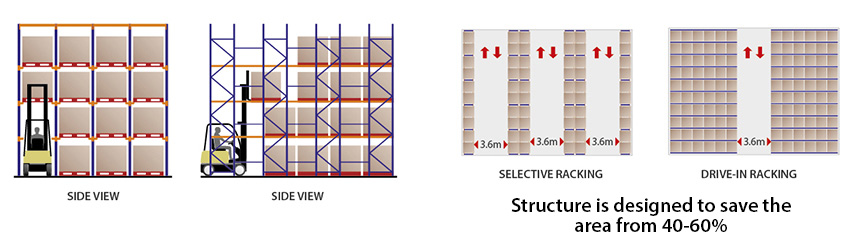

Drive in racking is also known as drive through racking. It is suitable for the storage of goods at same size by large quantitles, with higher space utilization and lower cost. It has no special channel for trollys and trucks, when storing goods the forklift operates from inner side to outer side, but oppositely when picking, that is called first-in, last-out.

2. WHAT IS ADVANTAGE OF DRIVE-IN RACKING?

Quality and Benefts:

• Very high utility ratio of the warehouse.

• Can first in - first out or first in - last out

• Structural steel construction for durability

• Pallet positions configure from 2 to 5 deep and 2 to 5 high deal for roofing

• Finish: Powder coating and various color be available.

• Suitable for storing few type of goods with large quantity

• Widely used in milk, drink industry, and also be welcomed by cold storage.

3. WHAT IS DISADVANTAGE OF DRIVE-IN RACKING?

• Last-In-First-Out inventory system limits what kind of products can be stored in a drive in rack.

• More common for forklift damage to racks with this type of racking because of the high amount of forklift traffic in and out of the system.

• Easier to lose product if it’s not well-managed.

•Poor accessibility to pallets that aren’t at the front.